Introduction

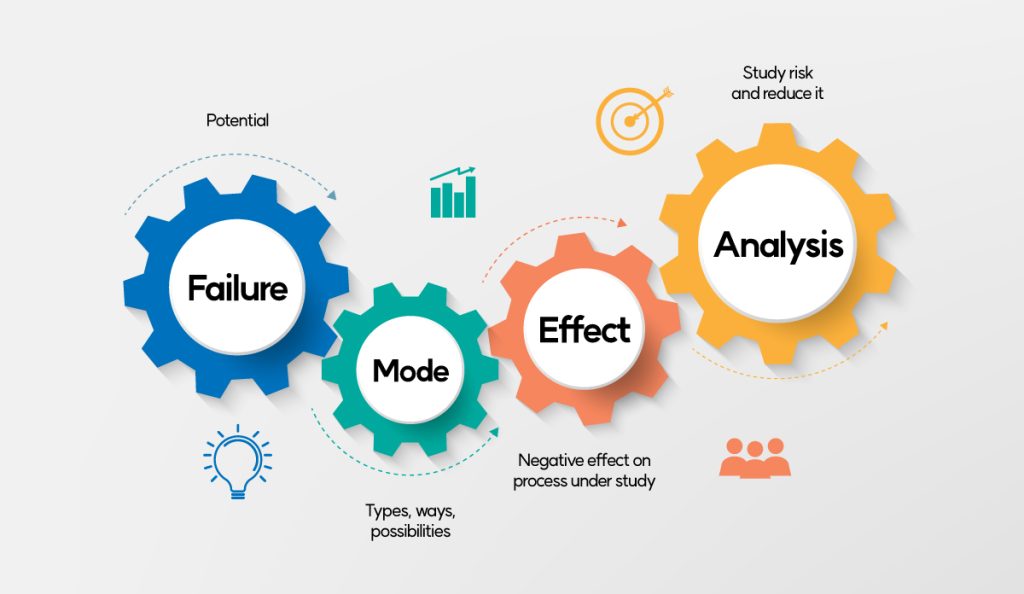

Failure Modes and Effects Analysis (FMEA) is a structured approach used to identify, assess, and mitigate potential failures in products and processes. This article highlights the significance of FMEA in risk management.

Steps in FMEA Process

- Identify Failure Modes – Determine potential defects in processes.

- Assess Severity & Impact – Analyze the consequences of each failure.

- Prioritize Risks – Assign Risk Priority Numbers (RPN) to failures.

- Implement Corrective Actions – Develop preventive measures.

- Monitor & Improve – Continuously update the FMEA process.

Applications of FMEA

- Manufacturing: Preventing defects in product assembly.

- Healthcare: Reducing medical errors and equipment failures.

- Automotive: Ensuring safety in vehicle components.

Conclusion

By implementing FMEA, organizations can proactively manage risks, reduce failures, and enhance overall quality standards.